ESG

Social

Flawless safety, flawless health for zero safety accidents

LS MnM constantly practices organized and systematic safety activities.

- Safety and health management

- Responsible sourcing

- Contribution to the local community

- LBMA RGG Compliance Report

Policy & Strategy

Safety & Health Management Policy LS MnM is fully committed to achieving the goal of ‘Zero Serious Accidents’ through its rigorous safety and health management system. Our management standards exceed Korean law requirements, and we announced our safety & health Management Policy in 2022 to ensure employee participation and compliance. We have strengthened our ability to execute safety and health management system by reorganizing the organization based on three principles: proactive management, regular management, and on-site management. To prevent serious accidents in the smelter, we have established an emergency response system and a monitoring system on MES through the ODS project to ensure the safety of our employees and local communities. In order to actively respond to the strengthened laws and safety and health management risks, we plan to increase the investment budget from 8.7 billion won in 2022 to 9.8 billion won in 2023.

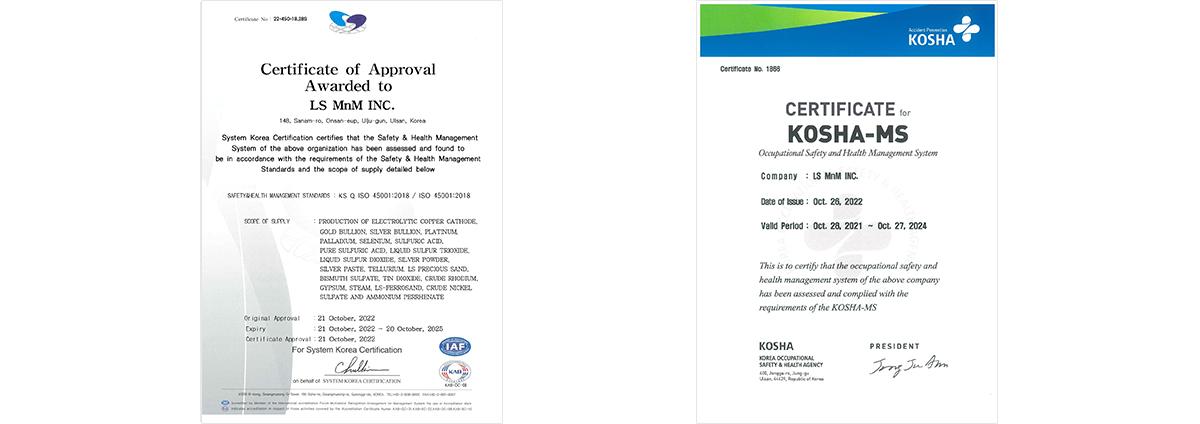

Certified Safety & Health Management System 'Safety & Health' is the most fundamental element in numerous industries including smelting. For systematic and continuous management for 'Safety & Health', LS MnM converted certification of KOSHA-MS(former KOSHA 18001) in 2021. Futhermore, LS MnM enhanced the management system of 'Safety & Health' by acquring ISO 45001 in 2022.

Organization

In 2022, LS MnM founded the Safety & Health Planning team directly under the head of Onsan Smelter & Refinery to oversee companywide safety and health management. We reinforced the roles of the existing Safety and Health Management team and formed a Safety and Health Innovation team to closely manage the site and provide field-oriented safety education. By subdividing the safety team and strengthening the organization by creating new teams, our company has secured the ability to execute company-wide safety and health. The Onsan Smelter & Refinery has an organizational system that meets the requirements of the Occupational Safety and Health Act, with the head of Onsan Smelter & Refinery as the person in charge of safety and health. The safety and health organization consists of the Occupational Safety and Health Committee, the Central Safety Committee, the Head of safety and health, safety and health manager, and Team manager. In addition, the Research Center and Seoul office have established a safety management system and implementation and monitoring is conducted based on the system with the head of Onsan Smelter & Refinery who is responsible for overall safety and health management. The head of Research Center put efforts on securing a safety in its labs with the assistance of Research Planning team. The head of Management Supporting Division takes responsibility to ensure safety in Seoul office while Administration and Public Relations Team advising all members on safety and health.

Process

Risk Assessment System LS MnM regularly conducts risk assessments according to an annual plan to minimize occupational risks. Risk assessment is managed through MES, and unacceptable risk factors are automatically registered in the system. Registered risk factors are immediately improved on-site and are reflected in safety assessments. Risk assessment is largely divided into two parts: work risk assessment and manufacturing risk assessment. Work risk assessment is conducted once a year through the Korea Risk Assessment System(KRAS). Manufacturing risk assessment is held once every 4 years through Hazard and Operability studies(HAZOP) and KOSHA Process Safety Review(K-PSR). Through these assessments, we regularly review the safety of our equipment and manufacturing process and minimize the risk of accidents.

Performance

Process Improvement: Leading To Zero Serious Accidents in 2022 LS MnM has reorganized its safety & health management organization prior to the implementation of the Serious Disaster Punishment Act. We established a comprehensive safety and health system and secured the ability to execute as per our motto ‘a smelter with perfect safety’. Moreover, we have established three principles as our serious accident prevention standards: proactive management, regular management, and on-site management. The Safety & Health Planning Team is responsible for proactive management, which includes implementing safety and health policies, as well as evaluating budgets and employees. Meanwhile, Safety & Health Planning Team is responsible for regular management, which includes providing safety and health training centered around implementation tasks, an inspection of harmful and risk factors, and follow-ups. Finally, Safety & Health Planning Team is responsible for on-site management, which includes managing on-site safety, leading onsite updates, improving risk factors, and building a safety culture. The Safety and Health Management Committee checks whether the business is in compliance with the laws and regulations and reviews safety and health-related issues by regularly inspecting the sites based on ‘compliance with safety and health obligations’ and ‘safety and health operation status by business site - headquarters, research center, Seoul office’ according to the Serious Accidents Punishment Act. Furthermore, they operate a meeting body consisting of safety and health experts and company executives semi-annually to review and advise major safety and health issues.

Workplace Safety Improvement Activities We carry out structured safety improvement activities that embody both pre- and post-accidents to achieve zero accidents and build a safe smelter. We implement on-site safety patrols to check and improve workplace safety management status based on the regulations and system of each division. We conduct on-site safety patrols using drones to improve our ability to manage high areas that are difficult to maintain regularly. A speaker is attached to the drone to provide guidance on safety operations. In addition to onsite patrols, we have been implementing the ‘1 Strike Out’ policy, which selects seven safety measure items with a high risk of serious accidents and investigates and imposes restrictions on individuals who violate them through interviews.

Workplace Emergency Response System To respond promptly in case of an emergency, we gather various emergency scenarios, such as fire, chemical leakage, power outages, and earthquakes, and conduct safety drills suitable for each division at least once every month. We evaluate and reward these drills, which has increased our ability to respond quickly to accidents and helped us build an emergency response training system in our workplace. Furthermore, we partner with relevant organizations to conduct a company-wide comprehensive emergency training at least once a year.

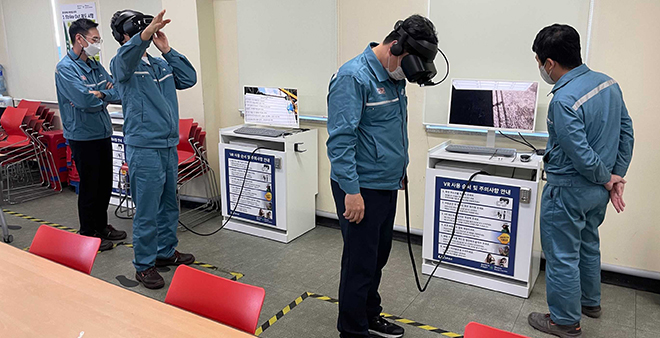

Education & Training LS MnM provides safety and health training in accordance with Article 29 of the Occupational Safety and Health Act. In order to turn online training into first-hand training that allows the indirect experience of on-site risk factors and accidents, we are conducting VR safety training for employees of our company and partner companies. We divided audiences by position for effectiveness, and we hired professional trainers to provide customized education.

Promotion of worker health LS MnM is making various efforts to improve the health of our employees. We have a health room where nurses are available for our employees and visitors. Additionally, an independent occupational doctor visits twice a month to treat patients with musculoskeletal system issues and provide one-on-one health counseling services. We also conduct comprehensive health exams regularly for employees and their spouses, and we have a policy to support medical expenses for their family members. Furthermore, we evaluate job stress factors once a year to ensure the mental wellness of our employees. Based on the results, we provide training, social activities, and informal small group activities. We also conduct regular blood donation campaigns for our executives and employees, and donate blood to vulnerable groups in the community.

System

Earthquake Warning System LS MnM has established an earthquake warning system that enables us to identify the magnitude of an earthquake in real time and respond promptly. In the event of a disaster, we utilize the system to alert and inform all locations within the smelter to prevent damage. Furthermore, we conduct annual emergency training by distributing cards with specific personal responsibilities to each department to prepare for any disasters.