ESG

Environmental

LS MnM's unrivaled technological prowess in the field of metal materials.

We are now taking a leap forward as an eco-friendly metal materials company based on our top-notch environmental management system.

Policy & Strategy

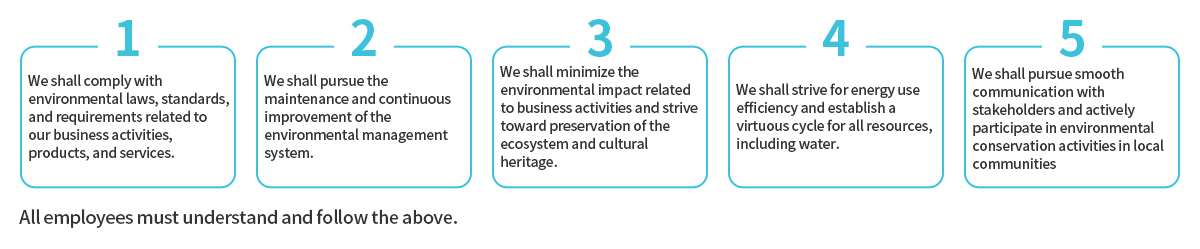

Environmental Policy In the year 2000, LS MnM established environmental management policy, with a clear recognition that environmental management based on compliance management is the foundation for becoming a Valuable Partner in Metals & Materials. Our environmental management policy contains a firm commitment that all members will comply with the environmental laws and regulations and continuously improve the environmental management system; minimize the environmental impact related to business activities; and actively participate in environmental preservation activities in local communities. We plan to strictly adhere to these environmental policies and achieve world-class environmental management.

LS MnM Environmental Management Policy

LS MnM employees clearly recognize that environmental management based on compliance management is the foundation for becoming a Valuable Partner in Metals & Materials, and declare the environmental policy as follows:

Proactive Environmental Management System LS MnM remains committed to improving its proactive environmental management system to minimize its impact on the environment. For instance, LS MnM is currently expanding its autonomous operating system to prevent pollution. As part of smelter’s digitization process, our company has installed an additional Tele Monitoring Systems(TMS) on top of the 24 required by law. Our ultimate goal is to attain optimization and intelligent automation of environmental facilities by developing optimal operation models in the future.

Certified Environmental Management System LS MnM has established the basis for an environmental management system based on the ISO14001 certification of the Onsan smelter & Refinery and is striving for efficient operation and development of the system. Our company first acquired ISO 14001 certification in December 2000, and we switched to certification based on the ISO14001:2015 standard in 2017. Since implementing the environmental management system, internal auditors have conducted yearly internal assessments, while certification bodies conduct regular follow-up assessments to ensure the system's adequacy is maintained and improved.

Organization

At LS MnM, Safety & Environment Support Department is operated under the smelter manager to manage the workplace environment. The safety & environment support department manager oversees a team of highly qualified professionals responsible for maintaining a safe and sustainable workplace environment. This team operates in compliance with various environmental laws, including the Air Quality Conservation Act, Water Environment Conservation Act, Waste Management Act, and Chemical Substances Control Act. They work in coordination with the production team, plant engineering team, and plant maintenance team to manage the overall environmental impact of the workplace. Furthermore, LS MnM has appointed a hazardous chemical safety manager for each department in addition to the safety manager required by law to ensure chemical safety. The appointed managers practice chemical safety management by regularly inspecting and improving facilities and training employees.

Performance

Environmental Investment In 2018, LS MnM formed a separate task force team(TFT) for environmental investment to discover investment opportunities to proactively address environmental issues. At our company, we recognize the importance of staying ahead of evolving environmental regulations and social expectations. To this end, we have plans to invest approximately 124.3 billion KRW between 2018 and 2025 in environmental initiatives that will further enhance our sustainability efforts. For instance, we have installed the building dust collection system (Factory1: 780,000(Factory 1: 780,000S㎥/h, Plant 2: 450,000S㎥/h) to prevent fugitive emissions of air pollutants, reduce fine dust, and contribute to improving the air quality of local communities.

Training and External Activities LS MnM is working hard on environmental training to enhance environmental awareness of our employees and partners. At our workplace, we hold a firm belief that the environmental awareness of each worker directly affects the overall workplace environment. That is why we consistently strive to develop educational materials tailored to our specific workplace. Starting from 2017, LS MnM has conducted chemical handling training for all workers and partners at the Onsan Refinery to foster this awareness among our workforce, and only allows people who have completed the training in our work site. As a non-ferrous metal company, we have taken measures to proactively respond to environmental laws and regulations and contribute to the establishment of national environmental policies. To this end, we have participated in enactment and revision of the integrated environmental management Technical Working Group(TWG) and Best Available Technique(BAT) initiatives. Additionally, we are actively participating in the Public Joint Response Council for Chemical Accidents and the Voluntary Agreement to Reduce HighConcentration Seasonal Fine Dust activities hosted by the Ministry of Environment and Ulsan City.

System

Environmental Protection Through Application of Digital Technology As part of our commitment to maintaining our position as a leading smelting business, LS MnM is striving to secure Global No. 1 competitiveness. To this end, we have completed Onsan Digital Smelter(ODS) as a part of our ongoing digital transformation in the production area. Our objective is to establish an autonomous safety and environmental management system that incorporates digital technology through the implementation of the ODS project(2017-2022). To achieve this goal, the CEO directly selected the best experts in each domain and formed a promotion organization. Our approach involves promoting field-oriented task discovery and internal manpower-oriented project implementation, backed by strong execution. Additionally, we aim to execute advanced ODS analysis tasks, based on successful cases in the past. In the environment sector, we have been invested in various tasks such as gas collection in the smelting process through autonomous control and real-time monitoring through the latest measuring equipment.